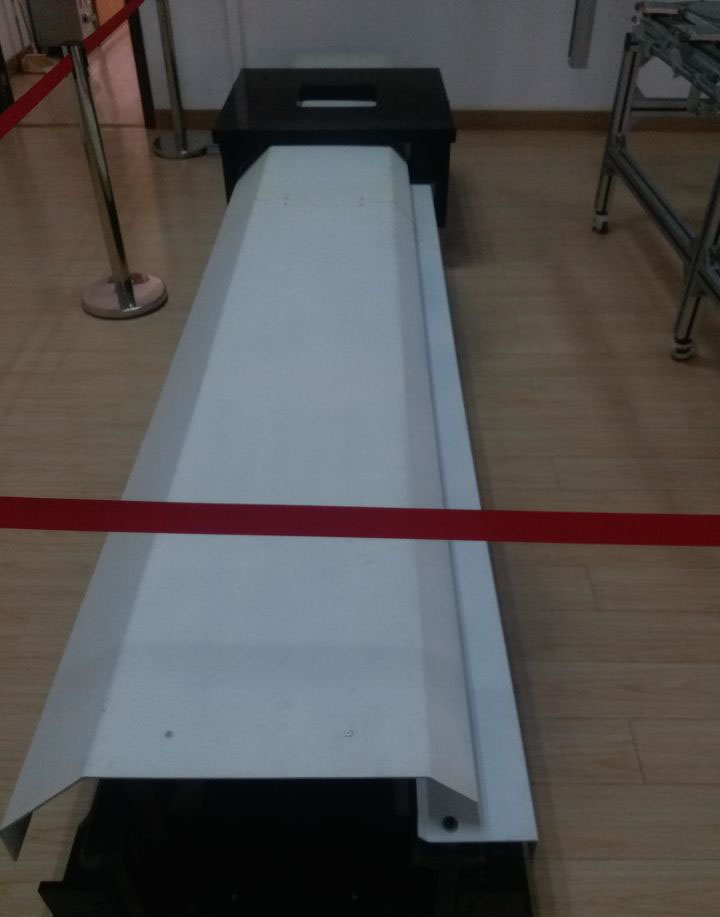

The seventh axis of the robot is also called the robot earth orbit, the robot sky orbit, the external axis of the robot, and the robot walking axis. Its role is mainly to move the industrial robot, so that it can move on the designated route, expand the robot's working radius, expand the scope of application of the robot, and integrate multiple devices into this linear system to improve the use efficiency of the robot. Develop and produce the seventh axis of robot, and customize the seventh axis of various specifications and precision requirements for customers. The seventh axis of the robot is mainly used in spraying, welding, handling, palletizing, casting, machine tool loading and unloading, intelligent warehousing, automobile, aerospace and other industries, and can be compatible with a variety of robot brands. Robot seventh axis classification According to the installation mode, it can be divided into ground rail type seventh axle and sky rail type seventh axle (forward suspension, side suspension and inverted suspension). According to the sealing form, it can be divided into open seventh shaft, semi closed seventh shaft and fully closed seventh shaft. According to the rolling elements used, it can be divided into linear guide type seventh axis and roller type seventh axis. Characteristics of the seventh axis of the robot 1. Excellent quality assurance, strong applicability (it is a robot walking shaft unit that can be used in many occasions), simple structure, low failure rate, reliable performance, easy maintenance, high rigidity, fast running speed, large payload, high repeatability, good protection performance, and customizable.

2. The seventh axis of the robot is convenient and practical, with less floor space, which is conducive to the layout of the production line in the plant. It can be set in a narrow space, and can be effectively used after on-site installation.